Fashion Production Standards - Production Costs

P R O D U C T I O N C O S T S

1-Yard Shirt

In our previous assignment, I chose to design the 1-yard shirt. Given current awareness of how unsustainable the fashion industry is, especially its production cycle and fabric waste, my main goal was to design a shirt that used all of the fabric and generated zero waste. Taking advantage of the lightness and "flowy" quality of the fabric, the intention was to create a design that looked structured but airy at the same time and also to use pleats as a way to give shape and reduce the transparency in certain areas.

One-Yard Shirt

Based on the "Alternate Assignment #1: Production Costs", I first developed a simple cost estimate using the actual time it took me to make the shirt or "first sample" and the price I paid for the fabric (I only purchased one yard). The original fabric is Kaufman St. Tropez Stretch Dotted, purchased at Fabric.com. I assumed an hourly rate of $20/hr for a starting fashion designer in LA. However, my actual hourly rate as an architectural designer is a lot higher.

Note: The 20% profit and variables are based on the "Rope and Padlock Belt" example.

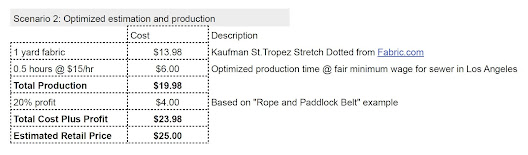

Scenario 1: Using original materials and timeframe

The total production cost and estimated retail price in the first Scenario seemed very high for the product. Obviously, given my lack of expertise and limited sewing skills, the production time was a lot longer than what it would take someone more experienced to make the shirt, or even myself if I started producing larger quantities and optimizing the process. I made a lot of mistakes that needed undoing and added extra steps that could be avoided. In a second scenario, I assumed an optimized production time and used the minimum wage for a much more skilled sewer that I could hire in Los Angeles for $15/hr, since my hourly rate is higher. The total production cost was much lower, at $19.98, and the estimated retail price of $25 with 20% profit seems reasonable for the garment.

Scenario 2: Optimized estimation and production

Now, if I wanted to mass-produce and sell at wholesale, I would probably purchase the fabric in larger quantities and try other fabrics that would give the same look-and-feel at a lower cost. The original fabric had a cost of $13.98 per yard and was not available anymore so, for a third scenario, I replaced it with Cotton Dobby Jacquard Dotts and assumed I would purchase 25+ yards with the discount on fabric.com. The total production cost was lowered to $11.60 and the estimated retail price (for wholesale) was kept at $25.

Scenario 3: Calculation for mass production to sell at wholesale

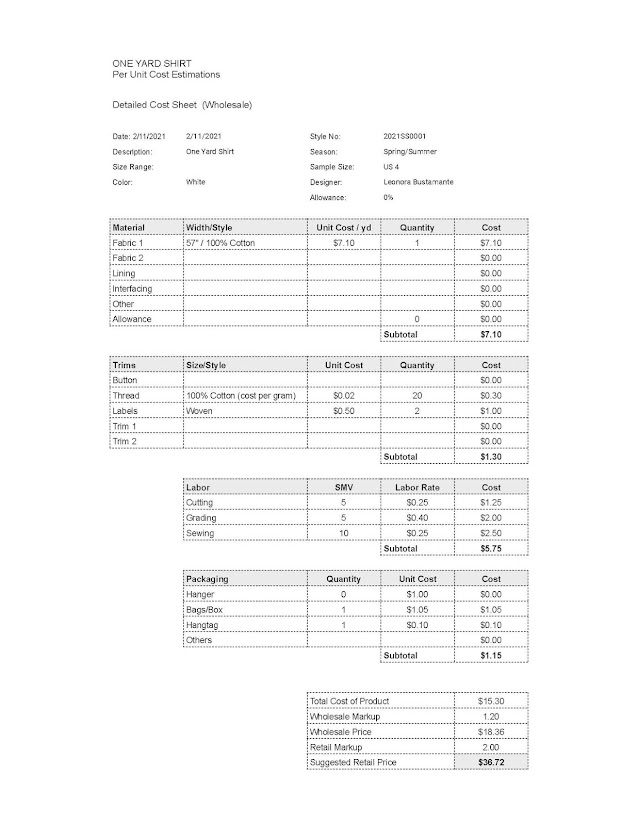

After finishing the exercise, I started wondering about packaging, labels, and other direct costs, I decided to do a more detailed analysis and develop a template that I could use for other future price estimates. The template is based on the Cost Sheet found in the book "The Fashion Business Manual. An Illustrated Guide to Building a Fashion Brand" by Fashionary.

Detailed Cost Estimate

In this final analysis, the total production cost is $15.30, which is a slight increase from the $11.60 on Scenario #3. The cost of the fabric is the same, but now I am adding thread, labels, and packaging costs, which is more realistic. Also, the labor costs are broken up into steps (cutting, grading, and sewing), with different rates according to the skills required for each process. For the wholesale markup, the same 20% is used, even though it is typically 55-62%, and the retail markup of 2.00 was added to the suggested retail price.

Comments

Post a Comment