Fashion Production Standards - Your Mockup

H&S Box Flap Bag

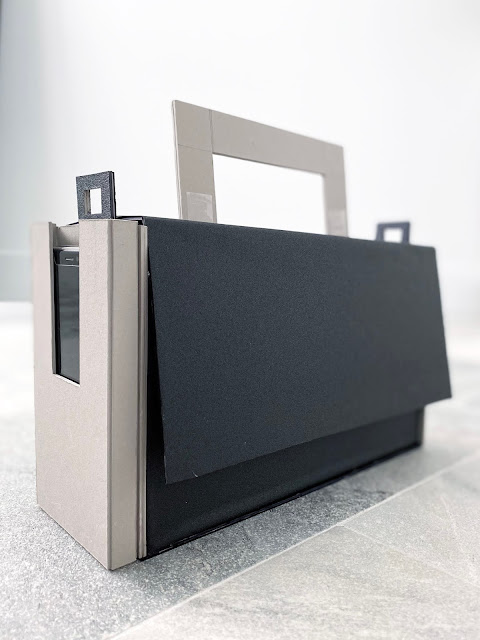

In a previous course, I designed a box flap bag with a hard interior casing and a "softer" exterior. In addition to the main bag, there is a removable interior pouch and customizable attachments, such as strap hooks and an exterior phone case. In terms of materials, the idea is to use either laser-cut acrylic or wood for the interior structure, leather for the flap and phone case, and metal for all the hardware, handle, and chain strap. The snap hook bottom piece could be an accent made in metal wood, ceramic, lightweight concrete, or a composite material that is scratch resistant.

H&S Box Flap Bag

The intention of the mock-up was to test how the pieces could come together, the size of the bag, the amount of material needed, and some of the "look and feel", even though it was made with museum board and vinyl covering. It also provided an idea of how long it would take to produce the bag and which pieces would need to be laser-cut or manufactured in advance. The original design did not have a top handle, so that was tested on the mockup first and later incorporated into the design. Also, the templates and parts were drawn and cut by hand, which turned out to be more time-consuming. For the first prototype, I would create new digital templates for all the parts and laser-cut most of the material.

Interior Details for "Slide-in" Removable Pouch

Since I have a digital 3D model of the bag and would need to produce digital templates, it is easier and more accurate to calculate materials and costs based on the digital files. Some of the costs are estimated and would vary depending on volume and quality.

The estimated production cost for the bag is approximately $260 and could be sold at $600-650. Some of the labor, such as laser-cutting and sewing/finishing of the later needs to be optimized and adjusted once the first prototype is fabricated.

Comments

Post a Comment